|

||||

|

||||

Technologies on Display

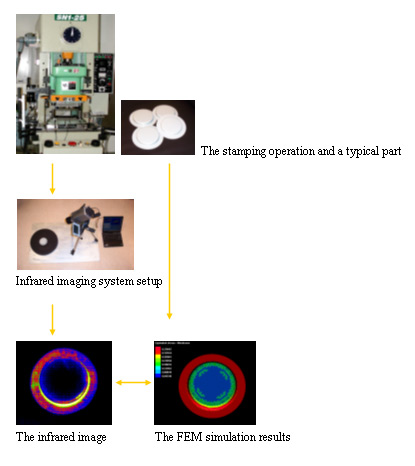

C3 - Diagnosis of Sheet Metal Stamping Processes Based on Thermal Imaging and Finite Element Analysis

Sheet metal stamping plays an important role in modern manufacturing. In Hong Kong and nearby Pearl River Delta area, there are some 10,000 factories that use sheet metal stamping. Owing to the ever increased demand for higher quality and lower production cost, monitoring and diagnosis are very important. The basic idea of the project is based on the fact that during the stamping, the sheet metal absorbs energy to deform. This energy is converted to heat and hence, by analyzing the heat distribution, we can diagnose the formability problems, such as large residues stress, uneven strain, etc. The thermal image is acquired using an infrared camera. The basic analytical tools include Finite Element Modeling (FEM), infrared image processing and similarity analysis

Applications

- Die design for sheet metal forming process

- Die setup in the start of a new stamping process

- Stamping process diagnosis

Features

- Advanced thermal imaging technology

- Advanced infrared image processing technology

- 3D infrared image reconstruction technology

- Integrated with finite element analysis technology

- Similarity analysis for stamping process diagnosis

Website

http://www2.acae.cuhk.edu.hk/~eml/projects7.html

Principal Investigator

Prof. Ru Xu DU

Department of Automation and Computer-Aided Engineering

¡@